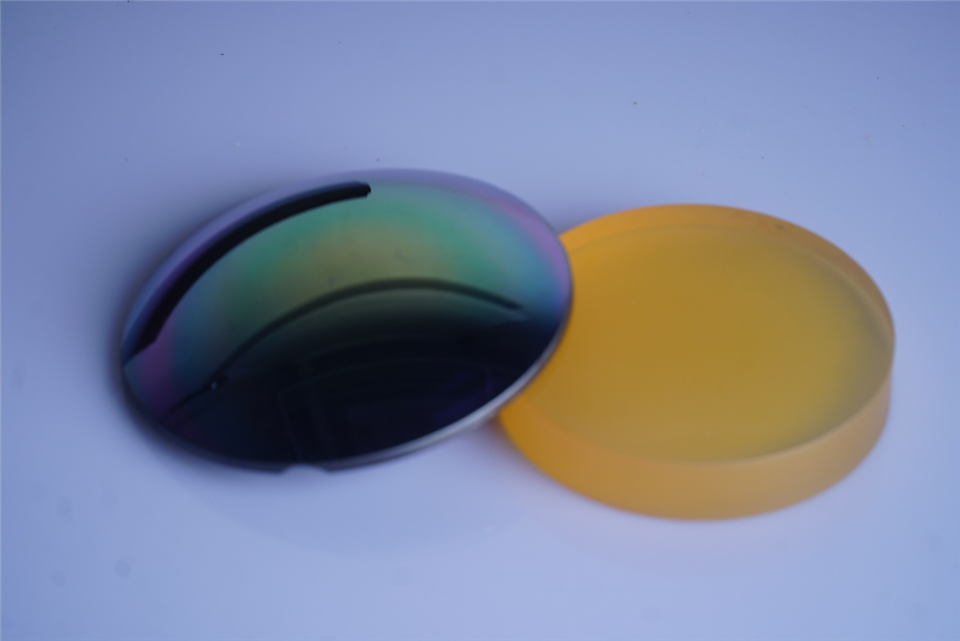

Optical Lenses

Perfect Optics is a cutting-edge technology company specializing in the research and development of optical equipment and processes, as well as the design and manufacturing of high-precision optical components and systems. With a strong commitment to technological excellence and top-notch customer service, we deliver premium optical solutions to clients across various industries. Our core business encompasses a wide range of products, including ultra-precision machining equipment (such as ion beam machining systems, robot machining systems, CNC polishing machines, and magnetorheological polishing machines), advanced coating equipment (ALD, IBS coating machines, etc.), precision components (ion sources, light control systems, magnetorheological fluids), ultra-precision manufacturing capabilities (for flat, spherical, aspheric, and freeform surfaces), and customized lenses and optical systems tailored to meet specific customer requirements.

Why Choose Us?

High Quality

Professional testing team, proven detection technology, supporting sampling and re-testing in all links to ensure perfect quality.

Rich Experience

Our company has more than 8 years experience in optics, engaged in professional equipment and production.

Advanced Equipment

Our has lupho scan 420, lupho scan 600, zygo, 4d and other ultra-precision detection equipment, We will make every effort to achieve the required accuracy.

OEM Service

With a strong commitment to technological excellence and top-notch customer service, we deliver premium optical solutions to clients across various industries.

What is Optical Lenses?

An optical lens is a transparent optical component used to converge or diverge light emitted from a peripheral object. The transmitted light rays then form a real or virtual image of the object.

Lenses are a good example of transmissive optical components, meaning that they pass or transmit light. Other transmissive components include filters, windows, flats, prisms, beamsplitters, and waveplates, while the opposite category — reflectives (which reflect light rather than transmit it) — include optical mirrors and retroreflectors.

Benefits of Optical Lenses

Precision Imaging

Optical lenses allow for high-resolution image capture, which is crucial in fields like microscopy and photography, where detail and accuracy are paramount.

Light Manipulation

Lenses can direct, focus, and disperse light, enabling the creation of specific visual effects or increasing the efficiency of lighting systems.

Enhanced Optical Performance

High-quality lenses improve the performance of optical devices, providing clearer, more accurate visual outputs for applications such as eyeglasses, cameras, and telescopes.

Across Industries

From medical imaging to entertainment, optical lenses are integral to numerous technologies, demonstrating their adaptability and importance across various industries.

Types of Optical Lenses

Single Vision Lenses

Single vision lenses have the same prescription power across the entire lens. Ideal for correcting myopia (near-sightedness) and hyperopia (far-sightedness).

Bifocal Lenses

Bifocals are made up of two lenses to correct both near and far-sighted vision. Bifocals have a visible dividing line between the two.

Trifocal Lenses

Trifocals are made up of three lenses to correct not only near and far-distance vision but additionally presbyopia, known as the inability to focus in the middle distance (caused by loss of flexibility in the eye’s lens).

Progressive Lenses

Progressive lenses are becoming an increasingly popular choice over bifocals and trifocals. Progressive lenses correct vision at near, middle, and far distances with no “transition zone” or visible divide.

Toric Lenses

Toric lenses are a type of single-vision lens used to correct astigmatism by adding cylinder correction, an additional prescription power.

Prism Lenses

Prism lenses correct heterophoria, a vision disorder characterized by the eyes not looking in the same direction when at rest.

Application of Optical Lenses

Astronomy And Satellites

The optical lenses used in astronomical and satellite-based applications need to provide a combination of extreme uniformity and the minimum variation of refractive index. The latest satellite systems make extensive use of imaging, communications, and remote sensing systems that are optically based, including earth to satellite and satellite to satellite communications.

Systems such as these make use of optical electrical components, including lasers, modulators, LEDs, and detection systems, all of which rely on high-precision optical lenses to operate over extreme distances and in sometimes hostile environments.

Projectors

The optical lenses used in projectors need to be high-performance components, offering high levels of transmittance with the absolute minimum of divergence and refraction. This is particularly true of projectors that provide ultra HD imagery on a large scale, which call for multiple optical lenses manufactured to the highest possible levels of quality and consistency.

Cameras And Phones

Even the most basic smartphones on the market today come equipped with high-quality cameras. Often, these cameras are used as the main point of differentiation between one model or brand of smartphone and the next. The optical lenses used in phones of this kind needed to be small and lightweight without sacrificing anything in terms of quality.

In many cases, the optical lenses in question will be aspherical lenses, which have been precision moulded to reduce or eliminate imperfections such as field curvature and chromatic aberrations.

Biotechnology

The phrase “biotechnology” covers a range of different sectors all of that make use of equipment which relies upon highly accurate optical lenses. Bio-optics often refers to the use of equipment such as microscopes – including specialised multi-photon and confocal microscopes – which require high-precision optical lenses to be manufactured to extremely tight specifications.

The lenses have to be extremely small in order to be practically useful.

Bio-optical imaging of this kind is then often combined with other technologies in order to deliver solutions such as monitoring the quality of water being supplied to people’s houses, checking the safety of donated blood used in transfusions and helping to diagnose a range of cancers and other conditions.

Environmental Monitoring

The urgency of climate change as an issue has thrown shed a new light on the importance of environmental monitoring. Optical lenses can play a pivotal role in equipment designed to monitor and track environmental data in order to make it easier to measure and combat climate change. This includes equipment designed to measure the following:

A: The intensity of sunlight

B: The presence of contaminants such as aerosols, trace gases and particulates

C: The presence and degree of air pollution

D: The presence of pollutants in either liquid or solid form in bodies of water

E: The emissions generated by specific facilities

F: The presence of hazardous materials within an environment

Medicine

Optical lenses play a vital role in a wide range of optical instruments used across medicine, from imaging systems to sensors and lasers. Specific examples include microscopes, endoscopes and ophthalmic instruments. Across the range of equipment which utilise optical lenses, the demand is for high-precision solutions that can be tailored to specific uses and environments.

Optical lenses used in endoscopes, for example, need to not only relay highly accurate images to the physician using them, but also to be small enough to be practically useful and robust enough to cope with not only the function itself but also any high-intensity sterilisation procedures. Examples of systems or devices that make use of optical lenses for medical purposes include the following:

A: Sensors attached to monitors

B: Equipment such as laryngoscopes, endoscopes and laparoscopes etc.

C: Optical systems used within surgery such as micro-cameras

D: Medical lasers

E: Fluorescence imaging systems

Material of Optical Lenses

Glass

Glass has historically been the material of choice for ophthalmic lenses. Glass is most stable, scratch-resistant, and provides the best optical quality of all lens materials. However, since glass is more brittle than most materials, lenses made of glass must be tempered or heat-treated to give them more strength and make them safer to wear. Glass is available in a number of indices of refraction. As mentioned above, the higher the index, the thinner a lens will be for a given power. However, the specific gravity also increases dramatically with the index making high-index glass lenses much heavier. Chromatic aberration is also more pronounced in high-index glass.

CR-39

Developed by PPG during WWII, CR-39, also known as plastic or hard resin, serves as a much lighter lens material (approximately 50% lighter) than glass. CR-39, however, is far less scratch-resistant and often must be coated to improve its scratch-resistant characteristics.

Polycarbonate

While its optical characteristics are less than ideal, polycarbonate, the same material used for bullet-proof glass, is the most impact-resistant of lens materials. Consequently, polycarbonate is the material of choice for safety and children’s eyewear. With an index of 1.59, polycarbonate also produces thinner, lighter lenses than glass or plastic. These factors along with polycarbonate’s inherent UV protection and pricing make it a popular material.

Hi-Index

High index lenses polymers typically refer to products with an index higher than 1.58. High index lenses require flatter curves than their lower index counterparts, resulting in thinner and lighter lenses. Furthermore, aspheric curves come standard in many high index products, particularly 1.66 and 1.70 products, and are available in 1.60. Asphericity reduces spatial distortion, reduces magnification or minification, and further helps maintain a thin and flat lens profile. High index material, however, tends to have a lower Abbe value which could potentially affect patients who are sensitive to chromatic aberration. Also higher index and flatter curves tend to result in more backside and inner-surface reflections. AR coatings are usually recommended for high index lenses to eliminate these reflections.

Trivex

Developed in 2001 by PPG, Trivex combines impact resistance of polycarbonate, exceptional optical clarity, and a specific gravity of 1.11 (the lightest available). Trivex’s tensile strength makes it ideal for drill mount frames. Trivex is available from Younger as Trilogy and from Hoya as Phoenix. All Trilogy products are aspheric and guaranteed for life against stress fractures and drill mount cracking. Some Phoenix products are now available with aspheric curves.

Mineral Lenses consist of many individual components that are melted into a glass mixture. In the first step, the raw materials, also known as “batch”, are melted into liquid glass to achieve a homogeneous blend. During the refining process, gas bubbles trapped in the batch are removed from the glass melt. The melt is then pressed into a minus or plus lens mould and left to cool down. The lens is then ground and polished, starting with the front face. This semi-finished product is also called a blank. It is then stored until an order is received for it. Only then will the back face be treated. Several grinding and polishing steps are necessary to match the required prescription.

Plastic Lenses are made of fully synthetic plastic material. The two production processes involved are chain polymerisation and condensation polymerisation. Chain polymerisation is a process of reacting monomer molecules in a chemical reaction to form long polymer chains. Condensation polymerisation is a process by which monomers carrying at least two functional groups are joined to form a macromolecule. During the process, simple by-products are given off, such as water.

Two different processes, casting or injection moulding, can be used to form the lenses. In the casting process, the liquid material is poured into a mould consisting of two halves and then allowed to solidify. In the next step, the semi-finished product is ground and polished as required. In contrast to the casting process, injection moulding can be used to produce large quantities. The molten material is injected under high pressure into a mould. After a short cooling time, the lenses have attained their shape with high dimensional accuracy. This process is mainly used for sunglass lenses since the quality of ground and polished cast lenses is far better.

How to Maintain Optical Lenses

Keep it clean. Keep it simple. To wash your prescription eyeglass lenses, eye care professionals suggest you gently rub your lenses clean with your fingers using warm, soapy water. Rinse them, and then pat them dry with a clean, soft cloth. Many optical suppliers sell ultra-fine, machine-washable microfiber lens cleaning cloths that trap dirt and dust. Try to avoid rubbing prescription lenses with rags, facial tissues or paper towels, as they could scratch your lenses. And definitely avoid using household cleaners, acetone or soaps with cream—as chemicals may damage your frames.

Storing your lenses in a sturdy protective case whenever you are not wearing them will go a long way towards preventing scratches on your lenses. Proper storage also helps to keep prescription eyeglass lenses clean while protecting your valuable frames. Never place prescription glasses in a purse, pocket or bag unprotected.

If setting your prescription lenses on a table or desk, it’s best to close your frames first before laying them down. Always set them frame-side down to avoid scratching the lenses. The floor is never a good place to leave your glasses. And when in the bathroom, remember: A sink or vanity top puts your lenses in an unfavorable position. Spatters, sprays and cosmetic products can quickly soil lenses. What’s more, anti-reflective (AR) treatments can be damaged by hairsprays or perfume.

Why Are High Index Lenses so Popular?

High-index lenses are recommended if you have a high optical prescription for nearsightedness, farsightedness, or astigmatism. Lenses that contain a higher prescription, are generally quite thick and heavy. This is because the lens needs to be a certain thickness to accurately bend light to correct the refractive error.

While both regular and high index lenses function in the same way, high index lenses are designed to bend light in the most effective way for more natural vision, and to eliminate the need for thick lenses.

High index lenses are thinner and lighter than regular lenses. These lenses are recommended for all types of refractive errors, but are ideal for those with strong farsightedness prescriptions— a thicker lens for this type of prescription generally produces a stronger magnification of the eyes. With the aspheric design of high index lenses, the center of the lens can be made thinner and create a flatter curvature— reducing the magnification of the eyes.

The following types of lenses are available in high-index materials:

A: Aspheric

B: Progressive

C: Polycarbonate

D: Photochromic

E: Polarized

High index lenses are generally scratch resistant and can fit into almost any frame. They can also be treated with special coatings to facilitate improved vision. Many people opt for the following coatings:

A: Anti-scratch coatings increase lens durability.

B: Anti-reflective coatings prevent light from reflecting off the lenses, glare, and halos around lights.

C: UV-protection coatings protect your eyes from the sun’s harmful rays.

What Are the Functions of Lenses?

Lenses are used in eyeglasses, microscopes, cameras, and telescopes, and their functions are to magnify or demagnify images to be seen. A lens bends a light beam at an aimed angle and converges or diffuses bundles of rays by taking advantage of refraction taking place when the light travels from air into glass or plastic. For that purpose, the side geometry of a lens has a spherical figure, which may be roughly divided into two types. One is a convex lens with a thick central part swelled outward and curved, and the other is a concave lens with a thin central part dented inward and curved. The convex lens converges light rays traveling parallel with each other to a point using refraction of light passing through the lens. The concave lens, on the other hand, spreads light rays traveling parallel with each other.

A point where bundles of rays are converged after being refracted through a lens is called a focal point. In concave lenses, the focal point is an extension of the beams of spreading light in a reverse direction. The distance between the lens and the focal point is called focal length. This distance varies depending on the thickness of the lens and the curve of the lens surface. In microscopes, cameras, and telescopes, the focal length is adjusted by combining convex and concave lenses, enabling you to see small objects magnified or to see something far away as if they are close by.

Our Factory

Perfect Optics is a cutting-edge technology company specializing in the research and development of optical equipment and processes, as well as the design and manufacturing of high-precision optical components and systems.

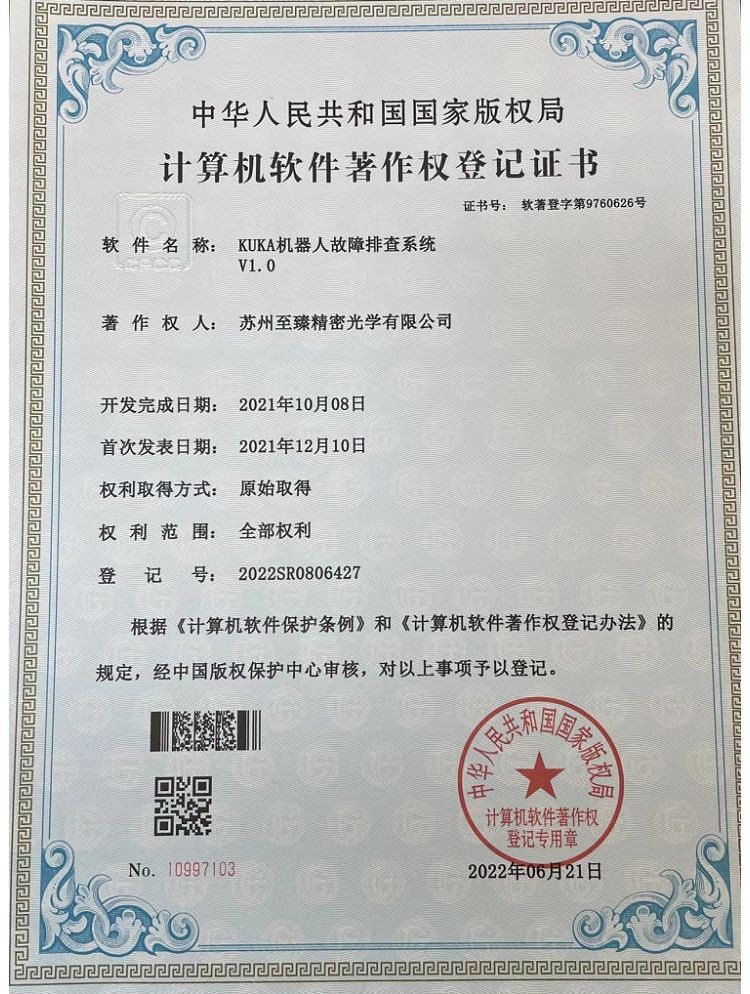

Our Certificate

FAQ

We're well-known as one of the leading optical lenes manufacturers and suppliers in China. If you're going to buy customized optical lenes made in China, welcome to get pricelist from our factory. For price consultation, contact us.

Ultra Precison Figruing Machine, Manual Focusing Lens, Ultraviolet Lithography Lens