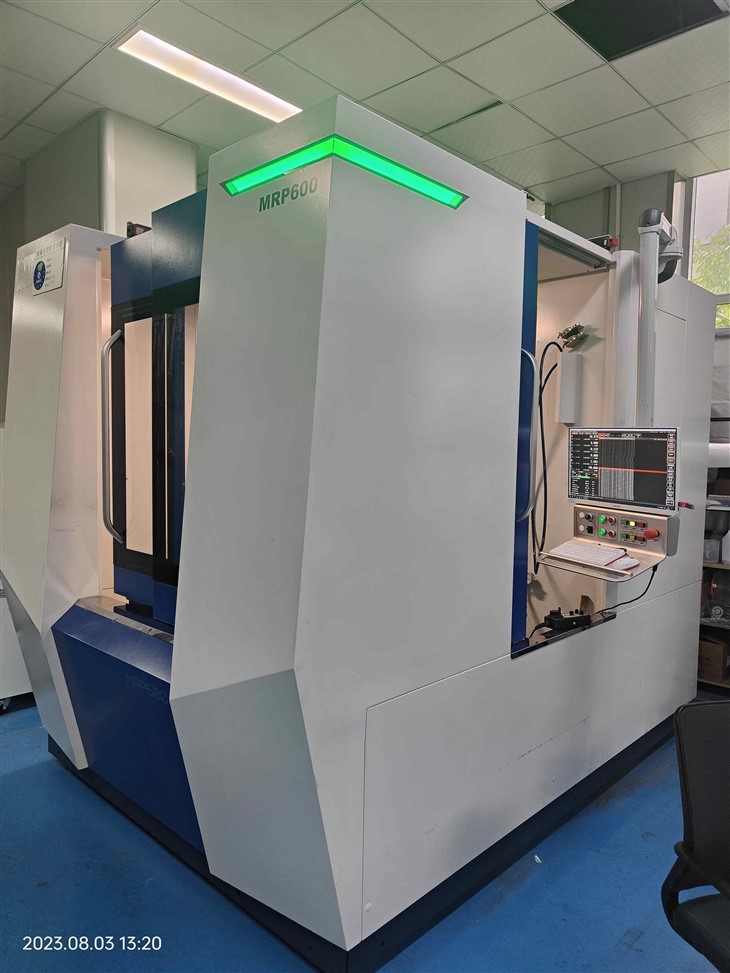

Magnetic Abrasive Finishing Machine is a kind of special machining equipment that uses magnetorheological technology to polish and grind. It uses magnetorheological fluid as grinding medium, and controls grinding force by adjusting the strength of magnetic field, so as to realize high-precision polishing and grinding of workpiece surface.

Magnetorheological polishing technology is an advanced optical manufacturing technology with high certainty, which mainly uses the controllable rheological characteristics of magnetorheological polishing liquid to process. It has remarkable technological characteristics such as high processing accuracy, convergence efficiency and extremely low surface defects. It is suitable for high-precision deterministic polishing of large-aperture plane, aspheric surface and free-form surface, which can make a breakthrough in improving the processing accuracy and production efficiency of optical components, and has broad application prospects in the construction of major national defense optical projects and the development of civil high-end photoelectric products.

Magnetorheological polishing machine is widely used in the fields of precision machining and surface treatment, especially for polishing and grinding brittle materials, high hardness materials and complex shaped workpieces. It has important applications in optical device manufacturing, mold manufacturing, aerospace parts manufacturing, micro-machining and other fields.

The Magnetorheological Polishing Machine is a highly advanced and innovative technology that is designed to make the polishing process faster, more efficient, and more precise. This machine makes use of magnetorheological fluid, which is a smart material that consists of tiny magnetic particles suspended in a liquid. When an external magnetic field is applied to the fluid, the particles align themselves and create a strong and stable gel-like substance that can be used for polishing and finishing.

One of the main advantages of the Magnetorheological Polishing Machine is its ability to remove material uniformly and consistently, thereby improving the surface finish and reducing the time required for hand polishing. It also eliminates the risk of human error and fatigue that are often associated with manual polishing. Additionally, the machine allows for easy and quick changing of polishing tools, and its automated controls ensure that the process is safe and predictable.

Another benefit of the Magnetorheological Polishing Machine is its versatility. It can be used for polishing a wide range of materials such as metals, glass, ceramics, and plastics, making it a valuable tool in various industries such as automotive, aerospace, and medical. Its ability to polish complex shapes and contours also makes it suitable for use in the production of molds and dies.

In conclusion, the Magnetorheological Polishing Machine is a highly positive and beneficial technology that enhances the polishing process while reducing costs and increasing productivity. Its precision, consistency, and versatility make it a valuable asset in various industries, and its application is set to continue growing in the future.

Hot Tags: magnetorheological polishing machine, China magnetorheological polishing machine manufacturers, suppliers, factory