Optical Polishing Machine

Perfect Optics is a cutting-edge technology company specializing in the research and development of optical equipment and processes, as well as the design and manufacturing of high-precision optical components and systems. Our core business encompasses a wide range of products, including ultra-precision machining equipment (such as ion beam machining systems, robot machining systems, CNC polishing machines, and magnetorheological polishing machines), advanced coating equipment (ALD, IBS coating machines, etc.), precision components (ion sources, light control systems, magnetorheological fluids), ultra-precision manufacturing capabilities (for flat, spherical, aspheric, and freeform surfaces), and customized lenses and optical systems tailored to meet specific customer requirements.

Why Choose Us

Professional Team

Backed by a team of highly skilled and experienced professionals with decades of expertise in the optical field, we have mastered the entire process of manufacturing optical components with nanometer-level precision and even sub-nanometer accuracy.

Advanced Equipment

Our has lupho scan 420, lupho scan 600, zygo, 4d and other ultra-precision detection equipment, We will make every effort to achieve the required accuracy.

Our Service

With a strong commitment to technological excellence and top-notch customer service, we deliver premium optical solutions to clients across various industries.

Types of Optical Polishing Machine

We offer the following Product introduce:

Staubli Optical Polishing Robot

Staubli optical polishing robot is a polishing robot system integrating intelligent technology, which can independently perceive the environment, make decisions and perform polishing tasks. The polishing machine adopts the advanced sensor, computer vision, machine learning, autonomous navigation and other technologies, so that it has a higher level of intelligence and autonomy, and can realize the deterministic polishing of optical components such as large-aperture plane, spherical surface, aspheric surface, off-axis aspheric surface and free-form surface.

Ion Beam Polishing Machine

Ion beam polishing technology is based on the principle of ion sputtering. In a vacuum state, the ion source leads the beam to generate a plasma energy beam, which bombards the surface of the workpiece to produce atomic-level material removal, thus realizing high-precision machining of optical components.

5-Axis CNC Optical Polishing Machine

5-Axis CNC polishing machine is an advanced CNC polishing equipment. Compared with 3-axis CNC polishing machine, it has more coordinate axes, usually including X axis, Y axis, Z axis, A axis and C axis. This equipment can carry out automatic high-precision polishing and polishing operations in five directions, and can realize more complex and precise surface machining of parts.

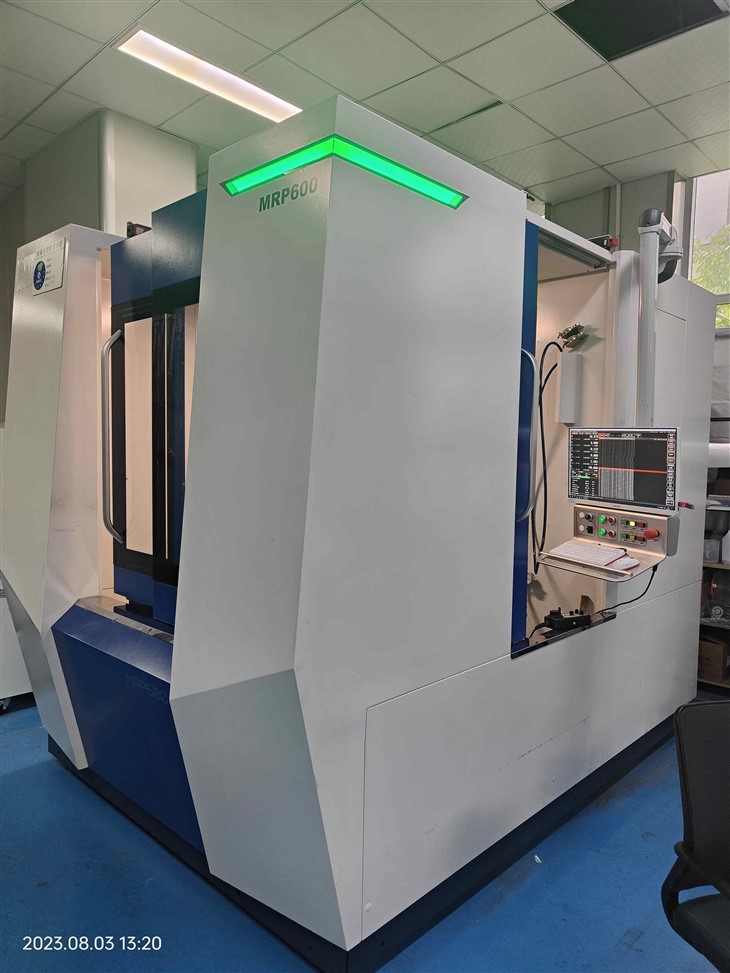

Magnetorheological Polishing Machine

Magnetorheological polishing technology is an advanced optical manufacturing technology with high certainty, which mainly uses the controllable rheological characteristics of magnetorheological polishing liquid to process. It has remarkable technological characteristics such as high processing accuracy, convergence efficiency and extremely low surface defects.

Product Specification

We offer the following Product Specifications:

|

Item |

Robot Polishing Machine |

|

Machinable material |

Fused silica, K9, microcrystalline and other optical elements, alloy aluminum and other metal elements |

|

Max machined size |

Ø2000mm |

|

Speed of polishing tool |

50-800 RPM |

|

Force sensor range |

Fx/Fy:100N; Fz:200N |

|

Force sensor accuracy |

Nonlinearity and trailing is better than 0.5%, crosstalk is better than 2% |

|

Force sensor resolution |

Fx/Fy: 0.09N; Fz: 0.33N |

|

Range of motion of tool shaft |

1: ±180 |

|

Max speed of tool shaft |

Axes 1-6 are 175°/s |

|

Repeated positioning accuracy |

0.06 mm |

|

Demand for area |

3.5mx3.5mx3m |

|

Temperature requirements |

22±0.5ºC |

|

Humidity requirements |

40%-80%RH |

|

5-Axis CNC Optical Polishing Machine |

|

|

Application |

Optical Polishing Centre for Spheres and Aspheres |

|

Working Range Diameter |

10 mm - 120 mm |

|

Working Range Diameter (aspheres - depending on workpiece aperture) |

10 mm - 200 mm |

|

Working Range Radius |

± 15 mm - ∞ |

|

Travel B |

-180 ° - 180 ° |

|

Travel C |

- 360 ° |

|

Travel X |

0 mm - 500 mm |

|

Travel Y |

0 mm - 250 mm |

|

Travel Z |

0 mm - 150 mm |

|

Amount of Axes |

5 (X, Y, Z, B, C) |

|

Control |

Siemens Sinumerik 840 D Solution Line |

|

Tool Spindle |

Speed: 0 - 2000 rpm; Interface: HD Chuck Ø25 x 42 DIN |

|

Workpiece Spindle |

Speed: 0 - 2000 rpm; Interface: HD Chuck Ø25 x 42 DIN |

|

Vacuum |

-0.6 bar |

|

Air Pressure Requirement |

6 Bar |

|

Power Requirement (others on request) |

8 KW |

|

Dimensions |

Width: 2100 mm, Height: 2000 mm, Depth: 2500 mm |

|

Weight (approx.) |

3100 kg |

|

Disclaimer |

All data are subject to change without notice. Please verify details with OptoTech. |

|

Ion Beam Milling (Polishing), Etching, Sputtering Machine |

|

|

Ion Source |

|

|

Ion Source |

Argon ions, optional xenon ions |

|

Ion Guns |

2 Diagonal ion guns (standard), can be controlled independently, 90°or 180°Position, Upgradeable to 4 ion guns |

|

Auto Milling |

Milling angle 0°~90° (standard milling angle 0°, other angles are mechanically adjustable) |

|

Ion Beam Energy |

0~6kV (low energy milling) |

|

0~10kV (high energy etching) |

|

|

Ion Current Density Peak |

10 mA/cm2 |

|

Gas Flow Control |

0~10ml/min adjustable |

|

Beam Spot Size |

300μm~500μm and 1.5mm~2.5 mm |

|

Polishing Speed |

Max 500μm/hr for Silicon (section or fixed-point etching and polishing); |

|

Max 100μm/hr for Silicon (plane etching and polishing); |

|

|

Max 10μm/hr for Silicon (planar spin etching and polishing); |

|

|

Milling Stage |

360° Continuously rotatable, for both plain & cross-section milling |

|

Rotation Speed |

6–10 rpm |

|

Vacuum |

|

|

Pump System |

Mechanical pump + turbo molecular pump in main body |

|

Vacuum |

Ultimate vacuum degree 5x10-3Pa |

|

Vacuum Gauge |

Digital vacuum acquisition system |

|

Specimen Airlock |

Vacuuming time for sample exchange 2.5 minutes |

|

User Interface |

|

|

Screen |

10” Color touchscreen, built-in computer and full auto control software system, can set all parameters, then start processing automatically. The system can be viewed & controlled from remote computer or mobile phone. |

|

Dimensions & Utilities |

|

|

Main Body Size |

L x W x H, 380x405x560mm |

|

Main Body Weight |

48Kgs |

|

Power Consumption |

Less than 1KW |

|

Power Supply |

220V±10%, Single-phase, 50Hz±1 |

|

Argon Gas (psi) |

25 |

Product Advantages

Staubli Optical Polishing Robot

One of the significant advantages of Staubli Optical Polishing Robot is its ability to provide consistent and uniform polishing results. The robot operates with an unparalleled level of precision, making it possible to achieve highly polished surfaces with no defects or imperfections.

5-Axis CNC Optical Polishing Machine

One of the key benefits of the 5-axis CNC optical polishing machine is its ability to precisely control the polishing process. Thanks to its advanced technology and programming, this machine gives operators complete control over the movement and speed of the polishing tool. This level of control ensures that every part is polished to the exact specifications needed, resulting in a high-quality finished product that meets or exceeds the strictest standards.

Magnetorheological Polishing Machine

One of the main advantages of the Magnetorheological Polishing Machine is its ability to remove material uniformly and consistently, thereby improving the surface finish and reducing the time required for hand polishing. It also eliminates the risk of human error and fatigue that are often associated with manual polishing. Additionally, the machine allows for easy and quick changing of polishing tools, and its automated controls ensure that the process is safe and predictable.

Certificate

FAQ

We're well-known as one of the leading optical polishing machine manufacturers and suppliers in China. If you're going to buy customized optical polishing machine made in China, welcome to get pricelist from our factory. For price consultation, contact us.

High Laser Damage Threshold Resistant Coating, ABB Optical Polishing Robort, Reflecting Mirror